Click HERE for our Technical Data Sheet (TDS) included with each block of Cosclay.

What is Cosclay?

Cosclay is a hybrid, plastic/rubber polymer clay that will remain strong and flexible after curing. Unlike other polymer clays, Cosclays’ unique flexibility imparts a durable and resilient quality that is suitable for endless applications, such as stop-motion characters, posable figures, one of a kind (OOAK) sculptures and much more! Cosclay allows for the creation of very thin and delicate pieces without the fear of breakage after curing, especially during transit. The possibilities are limited only by your imagination. What will you make?

Is there any latex in Cosclay?

There is absolutely NO latex in any of our clays or liquid mediums!

What’s the difference between COSCLAY - DOLL, DECO, and SCULPT?

The main differences between the 3 lines are color and working density. DOLL is available in 8 colors geared toward one of a kind (OOAK) artists and dollmakers and comes in Soft. SCULPT is designed for sculptors and model makers, has a Mid-tone Gray color and comes in Soft and Medium Firm work-ability. DECO is available in 8 standard, vibrant colors and lends itself well to traditional polymer clay techniques and decorative elements. The density is Medium Firm. All three lines are made fresh every day of the week and are easily condition-able right out of the package. (See our section below on how to rapidly condition large amounts of clay with very little effort)

What can I do with my Cosclay creation once I am finished with it?

You can reuse Cosclay to make something else while in clay form or you can bake your piece to permanently lock in the creation you made.

How thin can I make Cosclay?

You can a make it as thin or as thick as you want. The thinner the piece, the more rubbery it will cure and the thicker you make it the more like plastic it will be.

I have Sculpted and Baked my Cosclay but it is Rigid, not Flexible. Why?

Cosclay can be both rigid and flexible depending on how thick or thin you sculpt it. Pieces as thin as a leaf will be extremely flexible. Your design can also dictate flexibility. Long and thin pieces will also be highly flexible. You can use this flexibility to embed an aluminum wire to make a posable figure.

Can Cosclay be sanded or polished?

Yes it can, but because of its flexibility there is more surface drag than a rigid piece. Therefore, we recommend using a wet sanding technique to reduce surface drag. Cosclay can be sanded and ground down with Dremel motor tools and cut with various precision hand tools.

Once you’re satisfied with your creation, you can bake it in a home oven to convert it from its malleable form to a permanently flexible solid rubber/plastic. To do this, it is important to set your oven at the correct temperature and check that it is correct by using a secondary oven safe thermometer.

What temperature is best to cure Cosclay to get the optimal properties of the cured clay?

It is important to cure at 275°F (135°C) for at least 30 minutes per ¼” of material. If Cosclay is cured at too low a temperature, it will have a weak cure and will break when bent instead of flexing and holding its shape. Because Cosclay is temperature sensitive we do not recommend tabletop plastic dome style halogen convection ovens. Or small tabletop toaster ovens. We find that these types of ovens generate hotspots and uneven heating. While they may work for conventional polymer clays, they do not work well for Cosclay. The best type oven that provides the most even heating is a conventional home oven, either electric or gas.

This type of thermometer has worked well for the suggested methods: Taylor 3506 TruTemp: https://www.amazon.com/dp/B01LYE0RLV/

I noticed that sometimes when curing my creation that there is some steam that is made during baking. Is the steam hazardous?

The steam is not considered hazardous, but should be ventilated for good measure. Cosclay is made from all non-toxic ingredients. If you experience excess steam, it is likely that you are baking the clay at too high a temperature. Check your oven with a secondary thermometer to make sure it is baking at the correct temperature. Be sure not to burn the clay and keep it safely away from all heating elements. Larger pieces will sometimes generate more steam because there is a greater mass of material to cure. Cosclay is a professional medium and is not intended for use by children. Children can safely sculpt with Cosclay but any baking should only be done under the supervision of an adult.

To reduce costs and use less material, we recommend using aluminum armature wire over a tin foil core. We do not recommend using any kind of colored, plastic tape or masking tape over the foil as colors can transfer and bleed into your clay and ruin the coloration. This may be especially apparent with lighter colored clays.

What is the best material to cover my tin foil shape to secure it in place before I begin my sculpture?

The best material to use is an aluminum foil tape available at most hardware stores. This kind of tape is used primarily for sealing metal duct work and has a metal coating on one side and a specialty adhesive tape on the other side. Be sure not to confuse this type of tape with regular gray or colored duct/duck tape which will melt in the oven. Metal foil tapes are heat resistant.

Here is a link to the correct type of tape: Aluminum Foil Tape: https://www.amazon.com/dp/B01FROBUXE

I notice that when I make parts like limbs over a wire armature that Cosclay does not seem to adhere to the metal. When I flex my piece over the wire, I can feel the clay slide over the wire. How can I prevent this from happening?

One of the best and easiest ways to prevent this is to wrap a thinner wire around the primary wire to give the cured clay to more of an irregular surface to keep it in place. Another method is to add some thin layer of epoxy clay over the foil shell. Cosclay tends to stick better to epoxy than metal.

A couple of drops of Heat Resistant Super Glue works well too. Here is one: https://www.hotmelt.com/products/high-temperature-super-glue

I notice that my Cosclay cracked in spots after I baked it. Why did this happen?

There are a couple of reasons that this could have happened. First, you may have used a very thick section of clay and overheated it. When Cosclay gets overheated, it generates a steam that is trying to escape from the clay body. The easiest way for the steam to release is to rapidly push its way out by generating a crack for easy escape in the not fully cured clay.

The second reason for cracks after baking is caused by baking your piece once and then reposing it and baking again. When you do this, you are generating tension in the armature. Cosclay has a memory so when you bake it again, it softens and the areas that are bent put force on the new position and a crack will form wherever the new bend comes through. To avoid this problem, do not re-position your piece until after the final bake.

Can I bake my Cosclay, add new Cosclay and bake it again? Will the new clay stick to the cure clay?

The answer is yes! You can bake Cosclay repeatedly and new clay will stick to cured clay.

How many times can I bake my piece without losing the flexible aspect of Cosclay?

Cosclay is formulated to remain flexible after repeated baking. We have baked pieces dozens of times without any noticeable loss of flexibility.

How long will Cosclay last in its original container?

Sealed in its original packaging, Cosclay can last many years. Once opened Cosclay still has no specific expiration date as long as it is kept in a closed container. Exposure to air can cause a slow reaction (depending on the degree of humidity) that can result in slight drying. The drying effect can easily be corrected by kneading the clay and storing in a closed container. Another trick to ensure longevity of uncured Cosclay is to place it in the refrigerator. Cooled raw Cosclay will last indefinitely.

Can Cosclay be painted?

Yes. Cosclay can be painted with craft acrylics, pastels, Genesis polymer paints and some urethanes. (Test on a small, discreet area for compatibility.)

Does Cosclay contain any hazardous components?

No. Cosclay is made of 100% nontoxic ingredients and is phthalate free. It has been tested by a certified toxicologist and conforms to ASTM D-4236. Cosclay contains no hazardous ingredients.

Are any of Cosclays ingredients tested on Animals?

No. The polymers that cause Cosclay to cure are all made of plastic and rubber. None of the polymers are tested on animals and all of the remaining ingredients are derived from earth minerals and plants. There are no animal byproducts used to make Cosclay either.

Could Cosclay be considered a vegan friendly product?

In the sense that it contains no animal products or animal byproducts, the answer is yes.

How many Colors does Cosclay come in?

Currently, we offer 14 core colors but we expect new colors to be introduced in the near future. Note: As of August 1st, 2021, we have released three new trial colors: Sweet Sepia, Leaf Green, Passion Pink, and Bahama Blue.

What’s the difference between Soft & Medium Firm?

The Soft & Medium Firm densities are only specific to raw workability right out of the package. Both clay types result in the exact same resilience and flexibility after curing.

My clay is too Soft, what can I do to make it firmer?

If you find that your clay is too soft and want to firm it up a little bit, you can leach out some of the oils by placing thin sheets of your clay between two pieces of paper, paper towel, or cardboard for a few hours. Here’s a wonderful tutorial by our friend The Polymer Clay Tutor

Can Cosclay be used to create traditional polymer clay techniques?

Yes. Caning, Mokume-gane and other traditional techniques can be done very effectively with Cosclay.

Why does my Cosclay seem crumbly when I begin using it sometimes?

Immediately after production, Cosclay is quite soft. After a short time, freshly made clay will begin to settle into its specific density. All polymer clays need to be conditioned for best use. Having clay that appears crumbly at first is normal, but can be conditioned by hand or using our rapid conditioning method described below.

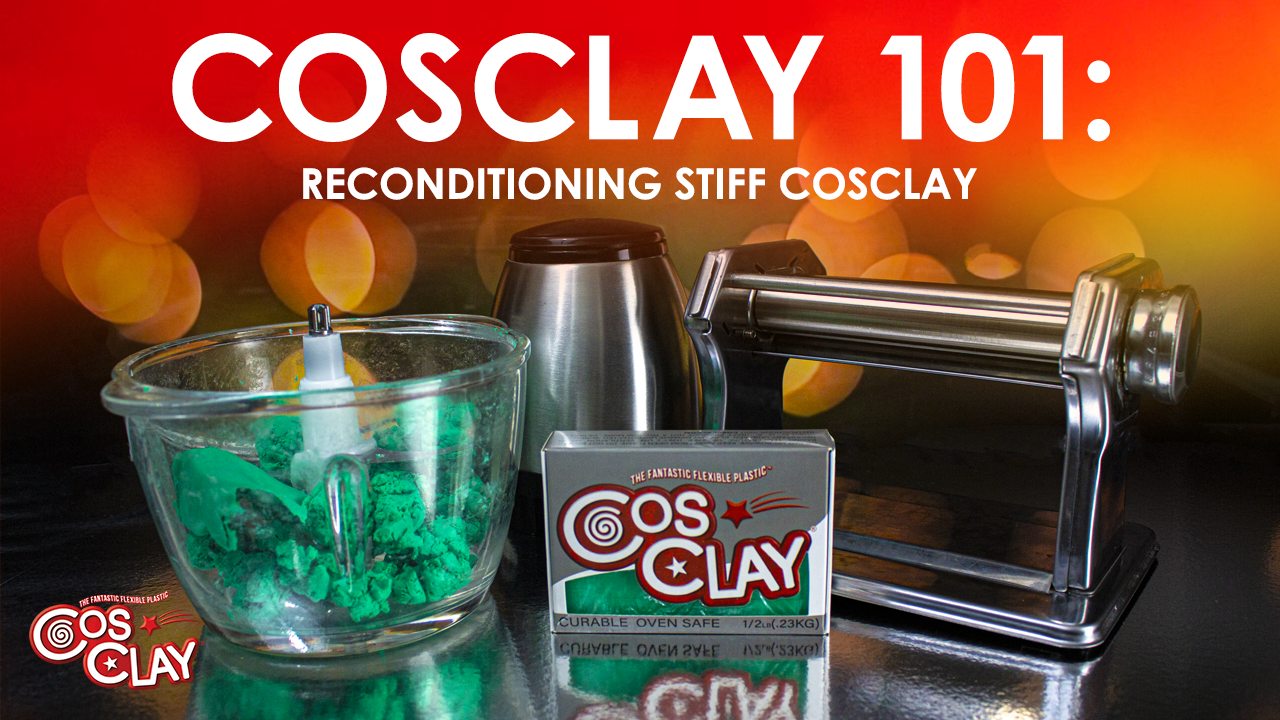

What is the fastest way to condition Cosclay?

For rapid conditioning, Cosclay blocks can be chopped up and added to a glass bowl food chopper/processor. The friction of the food processor will warm the clay and soften it quickly. (Firm clay can be more challenging to condition, so adding a few drops of Cosclay conditioner can greatly improve work-ability.) The resulting warm material can be placed in a pasta machine to make various sheet sizes for use in your creations. Or you can just use a pasta machine. Here are the links to both items: (See out video below for how it’s done).

Pasta Machine: https://www.amazon.com/Polymer-Machine-Cutters-Stainless-Handmade/dp/B0932S5X29/

What shipping services do you use?

Depending on the size and materials chosen for your order, we ship either through UPS or FedEx. PLEASE NOTE we are no longer shipping exclusively through FedEx Express as 2 Day Shipping is no longer guaranteed due to service changes.

What if I want my order shipped through a different service?

Sure! We have the capabilities to ship through UPS (Ground, Next Day, 2nd Day Air), USPS (Priority Mail and PO Box), and FedEx (Ground, Express) Let us know in the Notes section at the end of checkout (additional costs may apply. We’ll reach out to you via email with a PayPal link or we can process a Credit Card over the phone)

My order says it was shipped but the tracking shows it hasn’t moved. What’s the deal?

For UPS and FedEx we have a daily pickup Monday-Friday between 12pm-3:30pm EST (shop is closed on the weekends). For USPS/PO Box orders, Wednesday is our pickup/drop off day.

How can I find out if my order is delayed?

Generally if there's a delay like super freezing conditions (applies almost exclusively to liquids) or super hot temperatures (clays will start to cure around 135° F if left in the back of a delivery truck. We employ heat shield reflective envelopes during the Summer to negate this) we'll send you an email.

I need my order delivered to me by a specific date. How can I let you know?

There's a note section towards the end of the order page that we highly recommend adding specific "need by" dates or delivery instructions (we'll add post it notes taped down to the box with "deliver to back porch" etc.)